Having worked for Alfa Romeo for years, Enzo Ferrari became convinced that he knew how to create a team capable of building winning race cars. And he intended to do so under his own name. While Ferrari’s first factory was built in Modena, it is the second plant, set up in Maranello, that has become part of the brand’s legend.

Not even war could extinguish Enzo Ferrari’s ambition to produce race cars. The world’s fate was yet to be decided on the battlefields, and Enzo was already looking around for a suitable site to build a new, larger factory. The previous headquarters of Scuderia Ferrari was already too small and, on top of that, at risk of Allied bombing.

Enzo chose a small town called Maranello as the location of his new factory and began buying up the local farms in 1942. In the summer of 1943, the factory was already up and running, producing grinders and aircraft parts. In this way, Ferrari raised funds to build his first Ferrari car. His dream came true in 1947 when the 125 Sport model rolled out of the gate at Via Abetone. Interestingly, the plots of land that Enzo bought up in the 1940s were enough to accommodate the company’s entire present-day factory and the Fiorano racetrack, which opened in 1972. From the earliest days, Ferrari specialised in manufacturing racing models for the factory team and private racers, the so-called gentleman drivers. The first model to draw attention to cars with the prancing steed on the bonnet was the 166 MM and its many successes at prestigious European races. The world’s rich started knocking on Ferrari’s door, wanting to drive its cars — and not just in races. Hence, production at Maranello grew steadily: a total of 29 cars were built in the first three years. After two decades in business, over 700 cars were already leaving the factory each year.

The sale of most of Ferrari’s shares to Fiat in the late 1960s opened a new chapter in the brand’s history. It was then that Maranello began producing cars in the true sense of the word. Between the 1970s and the early 2000s, customised bodies made to customers’ specifications virtually disappeared. Within 10 years under Fiat, production quadrupled but still remained at an exclusive level, with 2,470 examples manufactured in 1980. Ferrari owes its successive growth to opening up to new markets — now operating 196 dealerships worldwide — and a broader and more comprehensive model range. Today, Ferrari produces more than 8,000 cars a year and this figure is set to increase by another 2,000 in the coming years.

The sale of most of Ferrari’s shares to Fiat in the late 1960s opened a new chapter in the brand’s history. It was then that Maranello began producing cars in the true sense of the word.

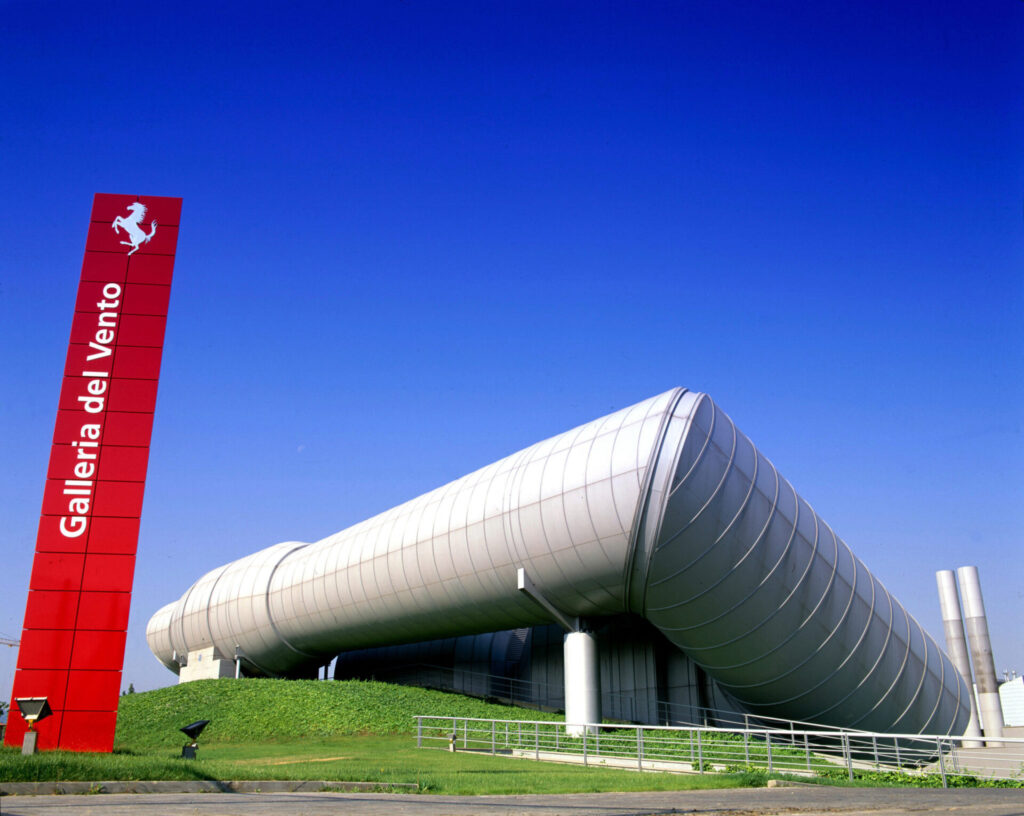

Since the 1980s, the factory at 4 Via Abetone Inferiore has changed radically. Its most recent refurbishment took place in the late 1990s. Led by the then Ferrari boss Luca di Montezemolo, the company created the Formula Uomo concept. It puts the employees at the forefront, focusing on their needs and creating a good working atmosphere. After all, in the case of Ferrari, much of the production is done manually. The effects of this strategy are apparent everywhere. The ubiquitous vegetation, which can even be found on the production line, is a delight. Not only is it good for employee well-being, but it also produces oxygen and absorbs pollutants. Ferrari employees are provided with bicycles (featuring the Ferrari logo, of course), which they use to navigate the streets bearing the names of champions who once raced for the Scuderia. The wind tunnel was designed by Renzo Piano, a renowned Italian designer. An on-site restaurant is located at the centre of the building complex, and the factory itself uses renewable energy sources in its operations. The culmination of this excellent approach to employees was the title of Best Place to Work in Europe, awarded to the Ferrari factory in 2007.

There are currently two main production lines at Maranello — one assembles cars with V8 engines, the other with V12s. A separate line was created for the LaFerrari and LaFerrari Aperta. The bodies are made beforehand at the former Scaglietti factory in Modena. Every day, 25 V8-engined Ferraris and eight V12 models leave the gates of the Maranello factory. Each vehicle spends three to four days on the production line before it goes to final testing preceding the delivery to the importer. Today, the factory is full of modern machinery, tools and special lifts. They speed up work and make it easier to assemble individual components. Moreover, they allow employees to do their jobs in a more ergonomic and comfortable environment. Yet it is still manual labour, and the result depends on the skills of hundreds of skilled craftsmen.